|

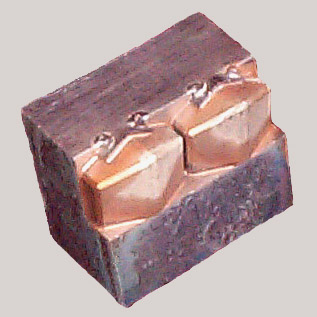

The photograph on the left is of a tungsten carbide tipped swing

hammer for a Duratech tub grinder. The hammer has been made using a

weldable tungsten carbide tipped hammer segment, consisting of a high

impact hammer tip, brazed with copper to a mild steel block. This has

been M.I.G. welded to the main body of the hammer, which is made from

Hardox 450, ensuring that the pin hole doesn't elongate during service.

Copper is used as a braze material because it is unaffected by the welding process and at the same time produces a high strength metallurgical bond. |