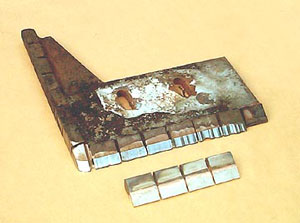

The photograph to the right shows the reverse side of the scraper and the large surface area of tungsten carbide, which has been running on the wall of the mill, keeping wera to a minimum.

Yes that is all this scraper cost! It is a floor and wall scraper out of an Eirich DE18 sand mill, which has an output of 50 tonnes per hour, running at Castings plc, Brownhills.

The mixer handles sand with a very high green strength, which is necessary to produce the correct surface finish on the castings produced.

Needless to say it causes severe wear problems on the mill, especially the floor and wall scraper.

Originally the mill was fitted with tungsten carbide tipped scrapers supplied by the manufacturers,

but these chipped badly because of the hardness of the sand and were not cost effective.

Eventually the company opted to use mild steel scrapers hardfaced using a welding rod with a very high percentage of tungsten carbide. However whilst these blades were better than the originals, the work of applying the hardfacing was very time consuming, unpleasant, and very expensive, because they only lasted 3 to 4 weeks.

The problem was solved by the development of a new design of WEAR-TECT-ITŪ tungsten carbide wear strip, shown adjacent to the scraper, which is a registered design (RD 3000642).

The scraper was fitted in April 2001 and was removed in September 2002, having processed well over 400,000 tonnes of sand. The cost of the scraper was approximately Ģ275.00, which equates to 1 penny for every 14.5 tonnes of sand processed.

The photograph to the right shows the reverse side of the scraper and the large surface area of tungsten carbide, which has been running on the wall of the mill, keeping wera to a minimum.

WEAR-TECT-ITŪ wear strips can be used for almost any application in sand preparation equipment and special pieces have been developed for:

Kunkell Wagner, Speed Muller, Dozamet, Eirich, FTL, Mitchells, and August Mills.

| Back | Main | Fields Of Activity. |